Introduction:

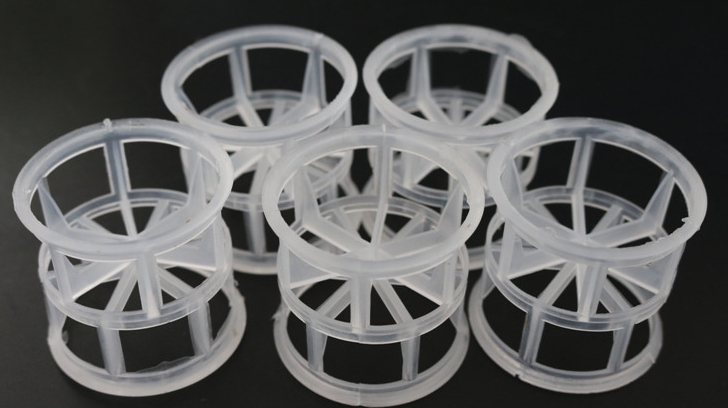

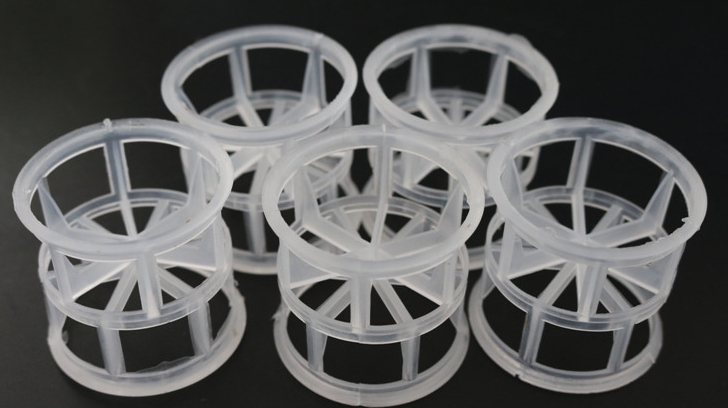

Pall Rings play a crucial role in enhancing chemical reactions within industrial reactors. Their unique design and material properties contribute to improved mass transfer, catalytic activity, and reaction selectivity. This article explores the applications of Pall rings in chemical reactors, their benefits, design considerations, and the impact on reaction efficiency.

1. **Mass Transfer Enhancement**:

Pall rings are renowned for their high surface area and open structure, which promote efficient gas-liquid or liquid-solid mass transfer. This enhanced mass transfer facilitates faster reaction rates and improved conversion efficiencies in chemical processes.

2. **Catalytic Support**:

In catalytic applications, Pall rings serve as excellent supports for catalyst materials. The large surface area and porosity of the rings provide ample space for catalyst deposition, leading to enhanced catalytic activity and selectivity in desired chemical transformations.

3. **Reaction Selectivity**:

The design of Pall rings allows for precise control over reaction conditions, leading to increased reaction selectivity. This enables manufacturers to produce desired products with higher purity and minimal unwanted by-products.

4. **Temperature Control**:

Pall rings contribute to effective temperature control within reactors. Their thermal stability and heat transfer properties help maintain optimal reaction temperatures, ensuring consistent and reliable performance across a range of operating conditions.

5. **Multi-Phase Reactions**:

Pall rings are particularly effective in facilitating multi-phase reactions, such as gas-liquid or liquid-solid reactions. Their geometry promotes intimate contact between phases, promoting faster reaction kinetics and improved overall efficiency.

6. **Design Considerations**:

When incorporating Pall rings into chemical reactors, factors such as packing density, bed height, liquid distribution, and gas-liquid flow rates must be carefully considered. Proper design optimization ensures maximum utilization of Pall rings for optimal reaction performance.

7. **Industrial Applications**:

Pall rings find extensive use in various industrial sectors, including petrochemicals, pharmaceuticals, specialty chemicals, and environmental remediation. Their versatility and performance make them indispensable in achieving desired reaction outcomes.

8. **Advancements in

Pall Ring Technology**:

Ongoing research and development efforts focus on enhancing Pall ring materials, optimizing reactor designs, and improving process control algorithms. These advancements aim to further enhance reaction efficiency, reduce energy consumption, and minimize environmental impact.

Conclusion:

Pall rings play a vital role in enhancing chemical reactions within industrial reactors, offering benefits such as improved mass transfer, catalytic support, reaction selectivity, and temperature control. By leveraging the unique properties of Pall rings and optimizing reactor designs, industries can achieve higher yields, improved product quality, and increased process efficiency in diverse chemical applications.