Introduction:

Tube settlers are critical components in water treatment plants, enhancing sedimentation efficiency and clarity. However, like all engineering systems, they are prone to operational challenges that can affect performance and reliability. This article delves into the common operational issues associated with tube settlers and proposes strategies for effective management and resolution.

1. **Understanding

Tube Settler Operational Challenges**

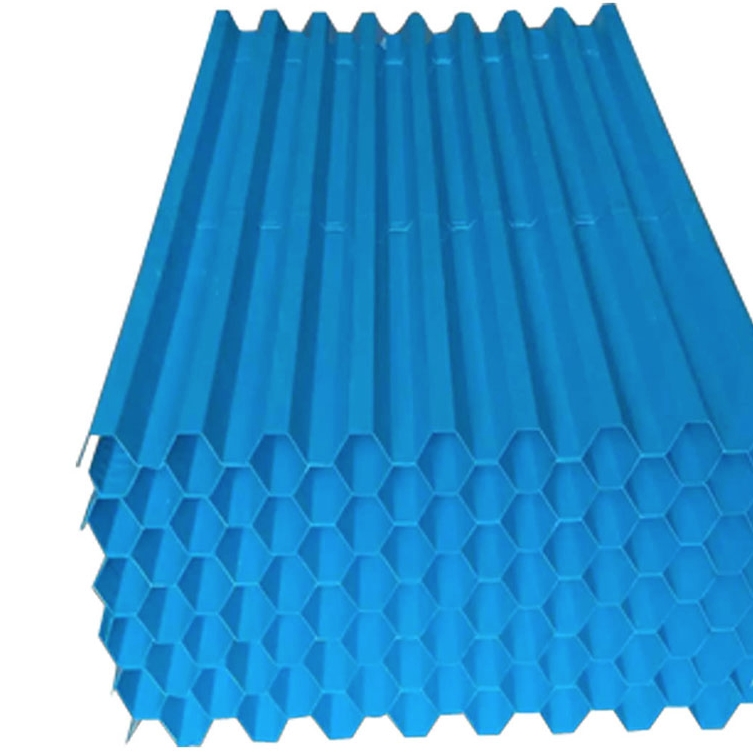

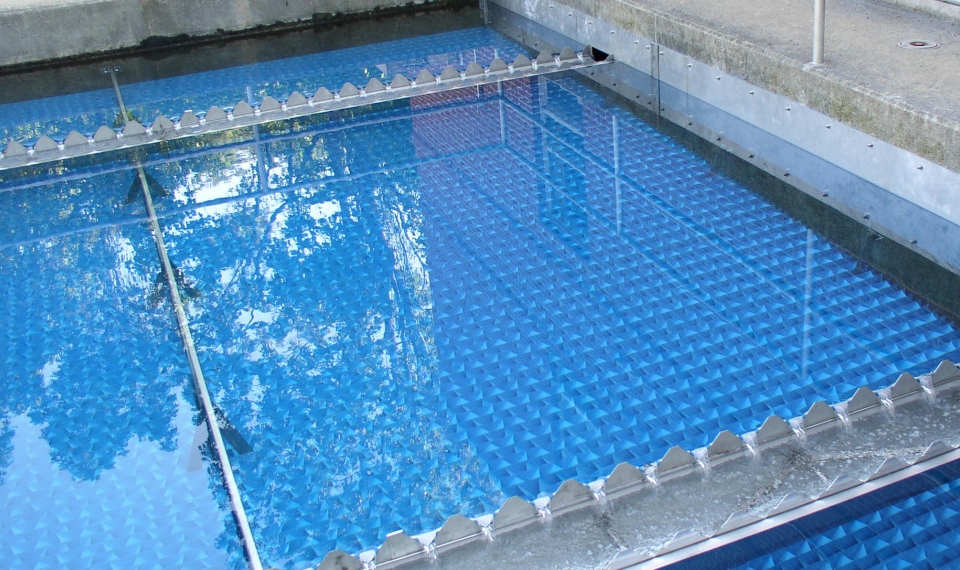

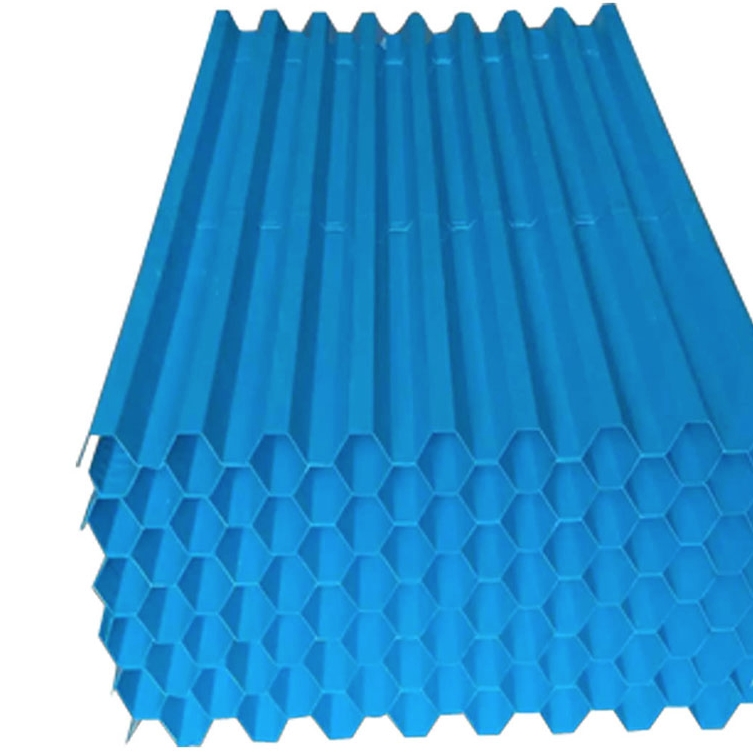

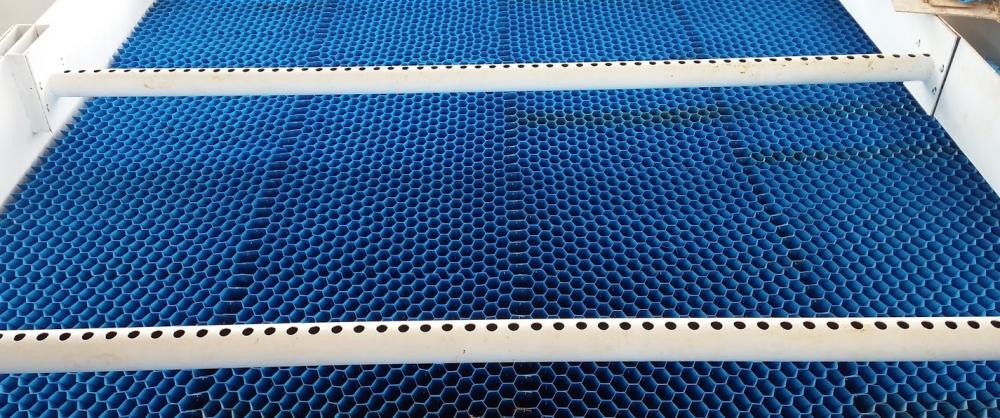

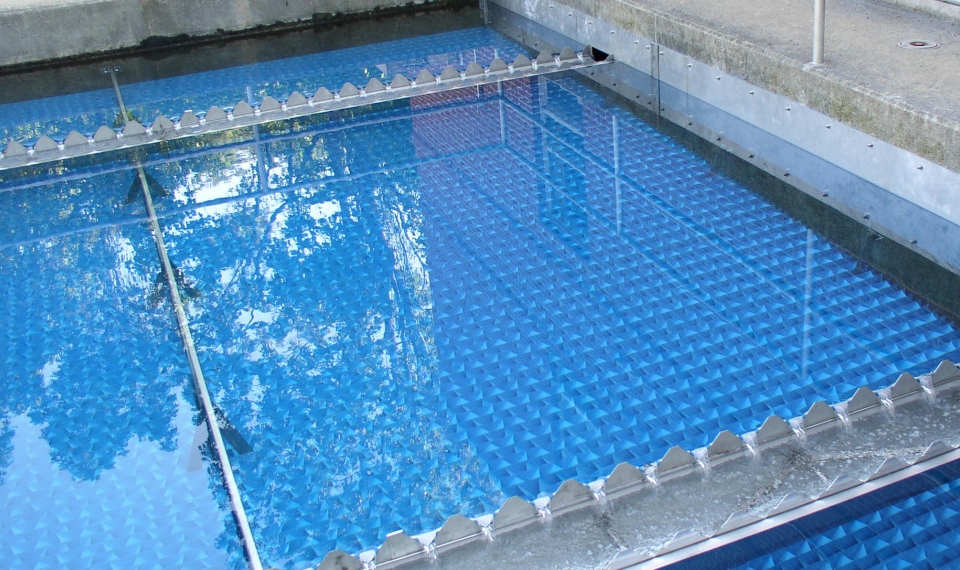

Tube settlers improve water treatment processes by increasing particle settling rates and reducing the footprint of sedimentation tanks. Despite their advantages, operational issues such as clogging, biofilm accumulation, and uneven flow distribution can arise, impacting their efficiency.

2. **Common Operational Issues and Solutions**

- **Clogging and Sediment Buildup**: Fine particles and debris can block the channels within tube settlers, reducing their effectiveness. Regular monitoring and cleaning are essential to prevent clogging and maintain optimal operation.

- **Biofilm Accumulation**: While biofilms can aid in water treatment, excessive growth can lead to reduced flow and efficiency. Implementing periodic cleaning routines and controlling nutrient levels in the water can help manage biofilm growth.

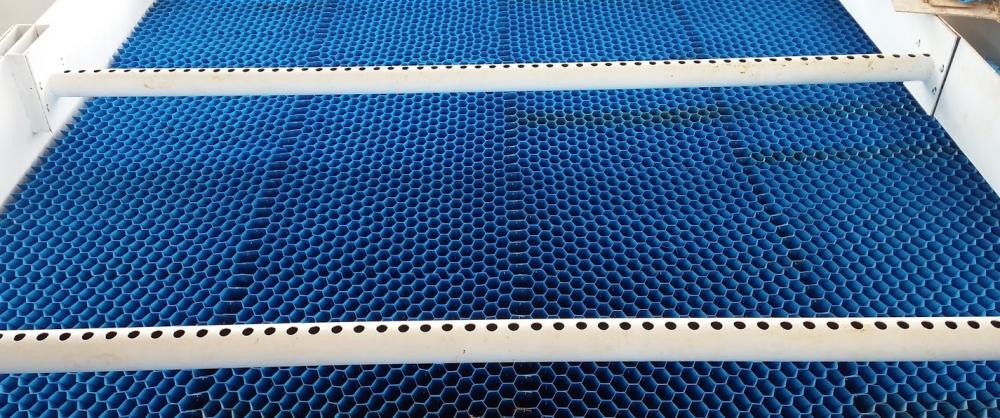

- **Flow Distribution Issues**: Uneven water flow can lead to reduced treatment efficiency. Modifying inlet structures or adjusting flow patterns can help achieve more uniform distribution across the tube settlers.

3. **Maintenance and Cleaning Strategies**

Effective maintenance and cleaning are paramount for the long-term functionality of tube settlers. Employing both mechanical and chemical cleaning methods can address various types of blockages and contaminations, ensuring consistent operation.

4. **Wear and Tear of Materials**

The materials used in tube settlers must withstand continuous exposure to water, chemicals, and physical stress. Selecting durable materials and conducting regular inspections can mitigate wear and tear, extending the lifespan of the system.

5. **Operational Efficiency and Cost Management**

Operational challenges can lead to increased costs due to maintenance, downtime, and replacement needs. Implementing a proactive maintenance schedule and optimizing operational parameters can reduce long-term costs and enhance system efficiency.

6. **Technological Advancements and Monitoring**

Advancements in monitoring technologies allow for real-time tracking of tube settler performance, enabling early detection of issues. Integrating these technologies can streamline operations and facilitate timely interventions.

7. **Training and Skill Development**

Ensuring that personnel are well-trained in the operation and maintenance of tube settlers can prevent many common issues. Continuous training and skill development are crucial for maintaining system efficiency and reliability.

Conclusion:

While tube settlers are vital for efficient water treatment, they are not free from operational challenges. Understanding these issues and implementing strategic management practices can significantly enhance the performance and reliability of tube settler systems. Continuous improvement in design, maintenance, and operation, coupled with advances in technology, will play a pivotal role in overcoming these challenges and ensuring the success of tube settler applications in water treatment.